English

7

5. Aim the LDM at the third desired target and press the

DIST (ON) button (E) once to record the third distance.

6. The calculated volume is displayed in the main reading line (S).

The third measurement is displayed in the additional reading

line (P).

NOTE: The final measurement is displayed as cubic feet or

cubic meters.

LASER MAINTENANCE

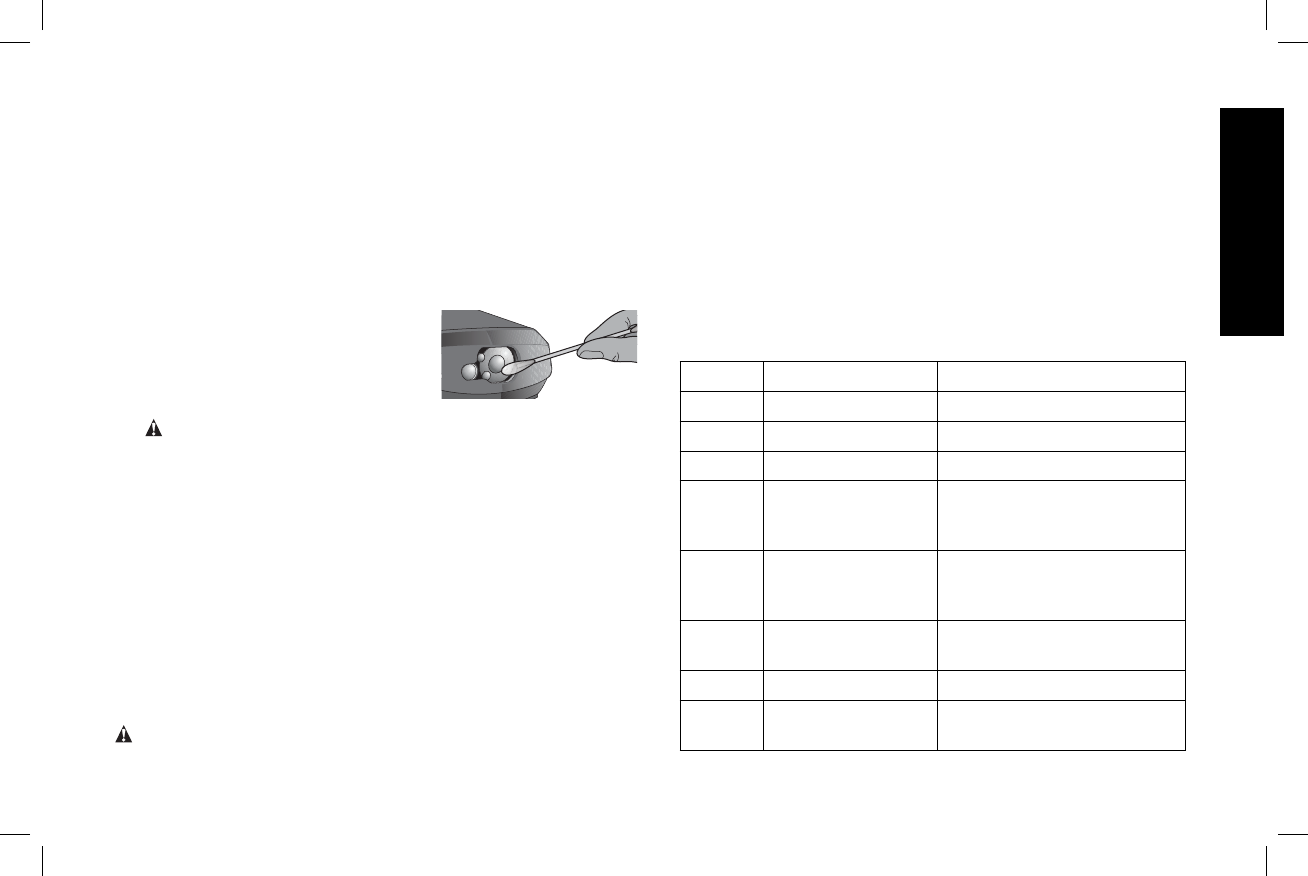

• Under some conditions, the lens of

FIG. 9

the laser emitter and the receiver

may collect some dirt or debris. This

will affect beam quality and operating

range. The lens should be cleaned

with a cotton swab moistened with

water as shown in Figure 9.

WARNING: DO NOT turn the LDM on while cleaning the

lens. Serious eye injury may result from staring at the beam.

• The housing can be cleaned with a wet lint-free cloth such as

a cotton cloth. USE WATER ONLY — DO NOT use cleansers

or solvents. Allow the LDM to air dry before storing.

• To maintain the accuracy of your readings, perform control

measurements periodically. Refer to Field Calibration

Check.

• If your LDM requires repair, contact your local D

EWALT service

center.

• When the LDM is not in use, store it in the pouch provided.

• Do not store your LDM in the pouch if it is wet. Dry exterior parts

with a soft, dry cloth and allow the LDM to air dry.

• Do not store your LDM at temperatures below 20˚F (–7˚C) or

above 160˚F (70˚C).

CAUTION: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the laser. These chemicals may

weaken the materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid get inside the

unit; never immerse any part of the unit into a liquid. Never use

compressed air to clean the laser.

Field Calibration Check

Measure a known distance [within a 10–30' (3–10 m) range] with

the LDM to confirm that the LDM is functioning properly.

Troubleshooting

If measurement conditions do not permit an accurate measurement,

an error code will appear on the LCD display. For an error code

description refer to the following table.

Code Description Correction

204 Calculation error Repeat the measurement

252 LDM too hot Let the LDM cool down

253 LDM too cold Warm the LDM up

255 Weak signal Change the target

surface (e.g., put white paper

on glass door)

256 Incorrect reading Change the target

surface (e.g., put white

paper on glass door)

257 Too much

background light

Shadow the

target area

258 Outside of range Stay within the working range

260 Laser beam

interrupted

Repeat the

measurement