3DOC.IG.QC01.1 Rev.: B December ‘06

En

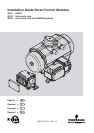

Fig. 3: Pneumatic connections

Double

acting

Control

Module cover

Single

acting

Ps

1/4”BSP or 1/4”NPT

Ra

Rb

Ps

1/4”BSP or 1/4”NPT

Rb

Venting

ports

OK

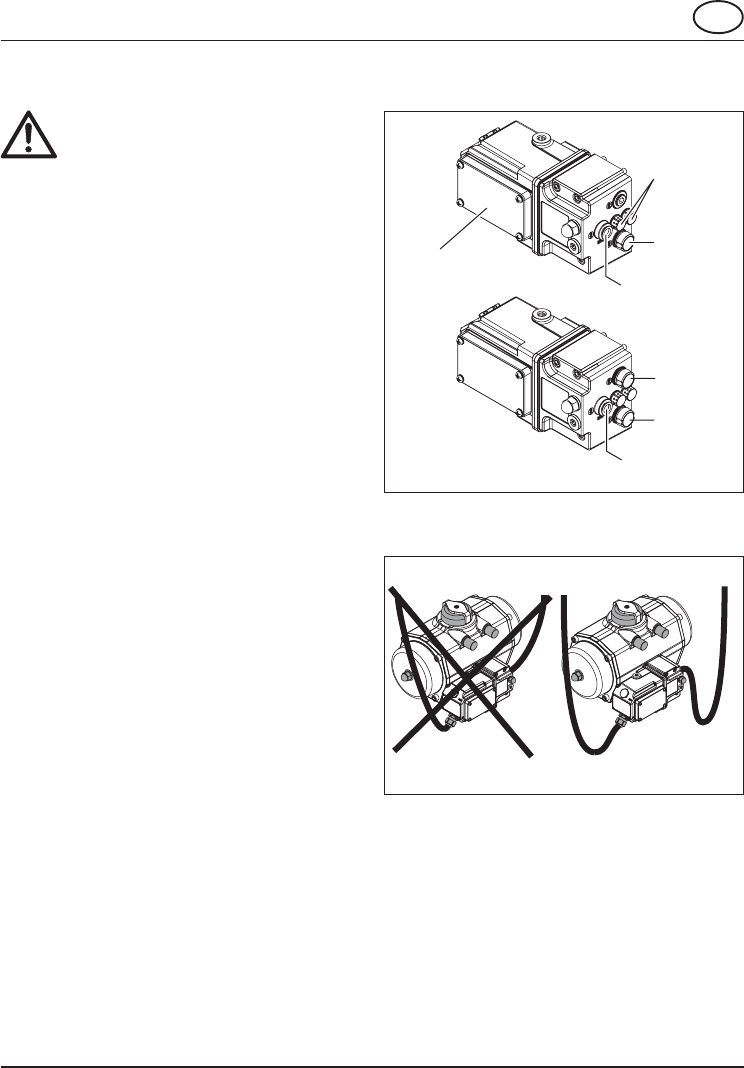

Fig 4 Install drip loops

3 Pneumatic connections

IMPORTANT

* The actuator/valve combination can move after

connecting the air supply.

* Ensure that the pneumatic Module and the Control

Module are mounted properly to the actuator to

achieve a degree of ingress protection rated IP65 /

NEMA4X before connecting the air supply.

* Check the maximum pressure P

max

= 8bar/116Psi

* Be sure that the minimum required supply

pressure for the application is available at the

actuator.

* Condensation or moisture that enters the actuator,

the pneumatic Module or the Control Module can

damage these components and can result in

failures. We strongly recommend to install drip

loops in cables in pipes (see figure. 4).

* The venting ports on the pneumatic Module (see

figure 3) are equipped as standard with silencers/

filters rated IP65 / NEMA4X.

* In case IP65 / NEMA4X ingress protection is

required, the exhaust ports Ra and Rb and the

electrical entries must be fitted with devices rated

IP65 / NEMA4X or higher.

3.1 Operating media :

* Air or inert gasses.

* QC01, air filtered at 50 micron.

QC03 and QC04, air filtered at 25 micron.

* Dew point 10 K below operating temperature.

* For subzero applications take appropriate

measures.

3.2 Single acting (spring return) or

Double acting actuator :

1 Remove the plug from the air supply (Ps).

2 Connect air supply to port (Ps).